Last Updated on November 27, 2024 by teamobn

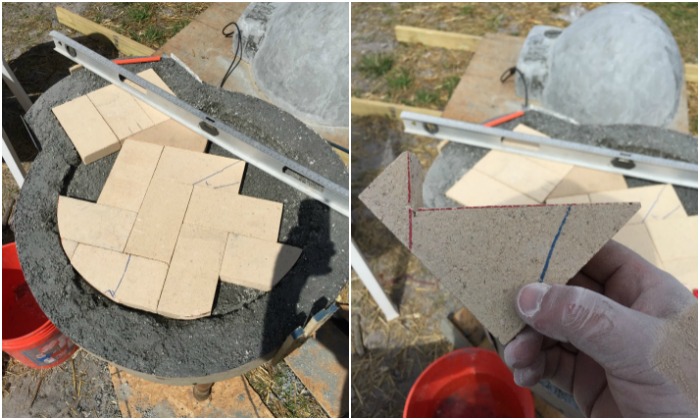

My fire bricks are 8.25 L x 4.125 W x 1.25 thick.

I wanted a total overall thickness of 2.25 for my floor. So the outside tracing I did of the (footprint) of the dome was by the bottom of my exercise ball pizza oven. I attached 2.75″ (2.25 for a total thickness of the floor, and .5″ so I could screw it to the edge of the plywood template) tall trim pieces of Formica around the entire edge, stapling, and screwing.

Then I took my inside circle and the inside of the door template and put a couple of pieces of wood to hold the inside circle in place at 1″ higher than the floor… Confused?

So the idea was that the main bottom template of my exercise ball pizza oven would get concrete up to 1 inch high/thick, then I would insert my inner mould in the entry and that would represent the space where the fire bricks would later go, and fill concrete the rest of the way, so the bricks would later be even with the rest of the floor concrete…

*Please don’t forget to put in the SS needles as I did. It seems to be a little brittle around a few edges because of that.

Fire brick floor of my exercise ball pizza oven: I wanted to lay out the floor in a herringbone, so that way it would not catch any edges putting in or out pizzas. I wanted to start with 3 full-sized pieces at the entrance. Peel can easily clear the first set. I didn’t want to have any crazy cuts but I ended up having 2.

I have laid tile in the past so I did have a little experience here, but the great part is that you can basically lay the tile on top and make a few marks on the tile and do the cut.

I started with a few rows down the middle of my exercise ball pizza oven and worked my way out from there. All in all, you want a tight fit and you’ll find a few bricks cut darn close and shoved in will kind of lock it all into place. Don’t over force it or it can break or damage something.

Bottom floor detail: So I later removed the bricks and did some fixing (brittle chucks lost due to not having any SS needles, so I think anyway) and skimmed the edge to give it a cleaner look. So once I skimmed the edges I came back later and smoothed and cleaned it.

(I previously forgot to mention this step due to not having any pics of it.)

I traced an outline of the footprint of the bottom section of the oven onto the cement board. Cut it out and mix up some Portland cement and used it as glue to put the bottom section of the oven onto the cement backer…

I then added the skim coat to the walls and the cement backer edge… making it all look like one uniform section…

Stand and pavers base: We had our spot picked out for some time. I tap-con(d) the heck out of some pressure-treated wood and sunk some 4×4 into the ground in the front of the table and used 2 x 4 to make a platform.

Overbuild this. My exercise ball pizza oven is only a few hundred pounds but I figured better safe than sorry. I think my platform was 45 inches long and 36 inches deep. We ran supports 12-15 inches and used 2-inch thick decking that a neighbour was throwing out.

You see from the pics that we do have it slightly turned. We have a vegetable garden right there and it looked better that way anyhow.

We also added some pavers for the oven to sit on. It seemed some opinions varied on the amount of space but you basically want at least 3″ of concrete or insulation if you have it on a wooden platform. I have seen people use less and more but 3″ seem to be the common number.

So we laid down pavers and I used my bottom section of the oven wood template to make my mark and cut to size. Look good no?

I didn’t take any pics of it, but we put a strap around the pavers so they wouldn’t move around and brought the base over and laid it on. Then we put 1 brick/ pavers (need to be slightly higher than the floor) at each corner (4 total, 2 at rear and 2 at front) and laid around the pipe or a wooden dowel.

I then mixed up a small batch of Portland cement and SS needles and troweled on a thin coat on the floor base. I basically used it as a “glue” for the two pieces.

(I did not take any pics of this process, but I added a pic with the firebrick floor so I could explain it. It is the perimeter surface around the fire bricks – not the front door entry curve – that 3-inch border.)

We then brought over the top and carefully put on the dowels or supports that you’re using spanning to the bricks. We then aligned it and lifted the rear, slid out the dowel, and carefully lowered it. then did it in the front.

Holy CRUD, they are together!

Just a few more details… Once they are aligned it was just a skim coat around the outside to seal the seam and my wife did all the detail work in the front.

I never would’ve had the patience my wife had to really make it look fantastic. If there weren’t the pics to prove otherwise floating around with family I would have claimed to have done it myself. But really I was taking pics and drinking a cold beer.

Obviously, it has not been fired up yet, I think we are going to wait about 3 weeks to make sure that we are good and cured. Just stick your face in the door and smell. If it smells damp or wet give it a few more days.

To fire cure, it, START SMALL. Do not put a roaring fire in there right away…

After 3 weeks we plan to do a small fire (2-3 twigs) let them burn completely and die out.

Then repeat the next day with a medium fire (3-4 twigs) burn and die out.

Then another medium fire… but add to it to keep it at medium fire for an hour or so

Then another medium to larger fire, burn for an hour…

Then you should be ready for a nice roaring fire.

Any cracks that occur you can fill later once the oven is broken in with the Portland SS mix…

When you get your fancy new exercise ball pizza oven equipment be sure to get a thermometer to keep an eye on temps.

Few additional photos I thought worth looking at: Took some additional photos that I thought were kind of important. The door opening is about 12.5 inches wide. I absolutely feel that is plenty.. like I had mentioned before, with 90 second cooking times one pizza at a time is perfect.

Also, I wanted to show the inside lip (where I get my 12.5″ inside measurement), the reason for the lip is that is what my door will rest against. The door will eventually be made so I have a few weeks to get that done.

I will be doing the door in the next few days. I will try to take some really detailed pic of the process and I noticed that I can do a video as well so I might attempt that.

All in all, after a few firings, I have indeed cooked a few things, pizza, wings, and so on, but forgot to take photos. I would like to see any improved versions that you guys can conjure up!

If you love this, you will also love our DIY cob oven project.

Thanks to William Stark for this great project!

Tips for Successfully Building a DIY Pizza Oven

Building a DIY pizza oven can be a rewarding project, but it’s important to approach it with the right materials and techniques. Here are some essential tips to guide you:

- Select the Right Materials:

- Use Lead-Free Firebrick: Opt for high-quality, lead-free firebrick that can withstand temperatures over 2500 degrees Fahrenheit. While they might be more expensive than regular bricks, they offer durability and superior heat retention, essential for efficient cooking.

- Build a Strong Support Structure:

- Incorporate Metal Supports: To ensure your firebrick stays securely in place, build a sturdy support structure using iron or steel. Angle steel and flat steel pieces can provide the necessary reinforcement for both the deck and roof of your oven.

- Choose the Ideal Base:

- Flat Stone Foundation: Start with a flat, stable base, such as flagstone, for placing your fire. This helps in managing cleanup and ensures a steady cooking surface, avoiding the mess and complication of dealing with ashes on gravel.

- Optimize Oven Design:

- Increase Layer Height: For better heat management and ease of use, consider making the base of the oven slightly higher than typical designs. This can enhance airflow and overall performance.

- Improve Heat Retention Techniques:

- Strategic Brick Placement: Utilize tools like a brick chisel and mallet to split bricks efficiently and create a well-sealed structure. Alternating bricks with tight seals can help in maintaining optimal heat.

- Practical Additions:

- Additional Surface for Warming: Place an extra layer like a flagstone paver on top of the oven. This can serve as a perfect platform to keep pizzas warm as they come out of the oven.

Focusing on these fundamental aspects can help you create a robust and efficient DIY pizza oven that enhances your cooking experience and delivers delicious pizzas every time.

Achieving Optimal Temperatures for Wood-Fired Pizza Baking

To craft the perfect pizza in a DIY pizza oven, it’s all about reaching the right temperature. Here’s a step-by-step guide to ensure your oven is primed and ready:

1. Start Early for Best Results

Timing is key. Begin preparing the fire several hours ahead of when you plan to bake. This early start allows ample time for the oven to reach the needed temperatures that cook pizzas swiftly and evenly.

2. Build a Solid Foundation

- Use Quality Wood: Select high-quality, dry wood, and split it into smaller pieces.

- Airflow Matters: Arrange a few bricks at the base of your oven to promote airflow. This setup aids in igniting the fire more efficiently.

3. Creating and Maintaining the Fire

- Initial Fire: Begin with small twigs and gradually introduce larger pieces as the fire strengthens.

- Coal Development: Your primary goal is to generate a robust bed of coals. These coals emit steady, radiant heat essential for the baking process.

4. Enhancing Heat Retention

- Coal Enclosure: Construct a partial wall with bricks around your coals. This setup not only concentrates the heat but also keeps the coals stable.

- Perfect Conditions: Hot coals below combined with flames above provide the ideal conditions for achieving the desired crust charring.

5. Finishing Touches Before Baking

- Final Flame: Just before baking, place a smaller piece of split wood on the glowing coals. This will naturally create a flame that circulates through the back vent, ensuring your toppings cook thoroughly while maintaining an optimal deck temperature.

By following these steps, you ensure your wood-fired oven is at the perfect temperature, resulting in pizza that boasts a beautifully cooked crust and perfectly melted toppings. Enjoy a slice of wood-fired perfection!

FAQ: DIY Pizza Oven

- What is the purpose of building a DIY pizza oven?

- A wood-fueled DIY pizza oven provides the high heat needed for a flawless crust and taste. This gadget can bake bread, roast meats, and smoke sweets in addition to pizza. Both a gourmet and practical solution, it provides steady cooking amid power outages and fuel shortages.

- How can you modify a basic oven design to improve its functionality?

- Enhancing a basic oven design improves performance and utility. High-temperature firebricks and steel reinforcing increase heat retention and structural support. Adjusting the base height, using a flagstone foundation, and splitting bricks makes the oven more stable, efficient, and easier to maintain.

- How can the design of a DIY pizza oven to achieve the best pizza dough recipe?

- Using excellent materials and careful construction improves a DIY pizza oven. For heat retention and durability, choose lead-free firebricks that can sustain above 2500°F and a solid iron or steel structure. Complete the design with 100% firebrick construction and tweak your cooking methods to maximize oven performance for great outcomes.

- What are the steps for using wood and coals to effectively bake pizza?

- Prepare excellent wood hours in advance, cutting it into smaller pieces for easy stacking and lighting, to make pizza using wood and fires. Start with a small fire and add larger pieces to create a deep bed of hot coals that distribute heat evenly. Continue adding wood to the fire, and right before baking, lay a tiny piece of wood on the coals for burst heat to cook the toppings and produce a crisp, uniformly roasted crust.

- What is the process for starting and maintaining a fire in a DIY pizza oven?

- Start and maintain a wood-fired oven fire by preparing excellent wood, breaking it into tiny pieces, and stacking it with bricks at the base for ventilation. Start with tiny logs and add larger ones to build a continuous fire and a deep bed of hot coals. Enclose the embers with bricks to retain heat, then add a tiny wood piece shortly before cooking to produce flames for balanced heat that cooks toppings and crust flawlessly.

- How much does it cost to build a DIY pizza oven using basic materials?

- A simple DIY pizza oven costs $200 to $250, including firebricks or clay bricks, refractory cement, and insulation. The oven’s dome and base are firebrick, refractory cement is heat-resistant, and insulation retains heat. Material quality, local availability, and whether you utilize reclaimed bricks or local vendors affect costs.

- How can steel be used to support the construction of a firebrick oven?

- Pizza oven stability and durability depend on steel. Steel beams or angles prevent heat or weight from displacing bricks. Steel trusses sustain brick weight and extreme temperatures, while a steel grid under the oven deck distributes weight uniformly. Steel components are tightly welded, making the oven strong and safe.

- What are the benefits of using lead-free firebrick over regular clay bricks?

- For wood-fired ovens, lead-free firebrick has various benefits over clay bricks. Firebricks resist fractures and deterioration better than clay bricks because they are heat-resistant. They absorb and transfer heat better, maintaining cooking temperatures. Lead-free firebricks also prevent toxins from leaking into food and ovens.

- What are some of the challenges encountered when using flagstone in oven construction?

- Safe and effective oven building using flagstone is difficult. Because it lacks heat resistance, it cracks or explodes under high temperatures. Flagstone has poor heat retention, creating uneven cooking and increased fuel usage, and salespeople overestimate its usefulness. Choosing firebrick or refractory cement improves durability and efficiency.

- Where can you purchase the materials for building a brick oven?

- Most hardware stores provide the items you need to create a brick oven. US retailers like Home Depot and Lowe’s carry what you need. You’ll need 47 8″x4″x2″ clay bricks to build a small brick oven. Two 16″x24″ concrete pavers are needed for the deck and roof. Sand and gravel are also available at these stores. This simple method is cheaper than pre-built brick ovens.