Last Updated on February 11, 2019 by teamobn

Apart from your house, your driveway is probably the most dominant feature of your landscape. Even if the distance from the road to your garage or carport is only 10 m, assuming your driveway is 3 m wide, that is a 30 m² surface area staring you and your guests in the face every time you walk out of your house or turn into your driveway.

Unfortunately, driveways often tend to be neglected. If the driveway is concreted, neglect will simply mean staining. However, if your driveway is paved, bitumen, hot mix, or gravel, neglect can quickly turn your drive into an untidy, potentially expensive, mess.

Driveway options

Gravel or aggregate:

This is usually the least expensive of all driveway options. There are many different aggregates of many different colours that can be used with great effect. However, it is essential that you test the aggregate for hardness first. Some aggregates can look wonderful at the quarry but are unable to stand up to the constant abrasion that occurs with traffic driving over it.

If you decide on a gravel or aggregate driveway, give ample thought to your edging. If the gravel is not contained, it will look unsightly and will drive you crazy as you constantly pull it out of your lawn or gardens.

A rockery edge is often the least expensive and most attractive solution. Consider embedding your edging in concrete in order to create a mowing strip on the outer edge. Without this mowing strip, it will be very difficult to trim the grass growing into and around your rock edging.

Another edging alternative is bricks. Laid properly, these will give an excellent edge to both your driveway and lawn or garden.

A third alternative is to use one of the many precast concrete block designs available from your local nursery.

It is strongly recommended that your gravel bed be at least 75 mm deep (3 inches). You will also find that coarse gravel does not pack down very well. A 10 mm gravel will generally give the best results.

Bitumen:

At first glance, bitumen appears to offer a distinct price advantage over other “hard” surfaces like concrete or hot mix. However, unless your need is relatively temporary – less than five years, you will probably find that the savings quickly disappear when you need to resurface the bitumen.

The major challenge with bitumen is that it is only a thin coating sitting on top of road base or crusher dust. Unfortunately, weeds will find their way through both the crusher dust and the bitumen over time. This will be most prevalent at the edges of the bitumen. Once the process starts, it is irreversible because the bitumen surface, once broken, becomes subject to constant wear and damage from weather and vehicular and pedestrian traffic.

If you do decide to use bitumen, pay special attention to the edging. Bitumen drives are typically edged with timber however, this will not prove to be durable over time. It is strongly recommended that you use a brick edge set in concrete. This will prevent the edges of the bitumen breaking up for a longer period of time than would occur with timber edging.

Hot mix:

Also known as asphalt concrete, blacktop, pavement and tarmac, this bituminous product sits between bitumen and concrete in terms of cost and durability. One advantage of hot mix is that it is now available in a range of permanent colours. However, given that even the best laid hot mix does not have the durability of concrete, yet costs about the same per square metre, it is rarely regarded as a domestic driveway solution.

If the ground on which the hot mix sits is stable and is not subject to significant temperature variations, hot mix can be expected to have a 10 year life assuming it has been laid on a properly prepared surface.

Unfortunately, in common with bitumen, once damage occurs, it spreads rapidly unless immediate repairs are undertaken.

Concrete:

The most common surface for driveways is concrete. It is strong, impervious to weeds, and requires minimal maintenance to remain serviceable. One challenge many people have with concrete is the glare that bounces off the natural product. To overcome this, concrete drives can be finished in a number of ways.

For example, an exposed aggregate finish could be used. In this process, the concrete is hosed down in the very last stages of drying in order to expose the gravel (aggregate) contained in the concrete mix. It’s important to ensure that your concrete supplier knows that an aggregate finish is intended. This will ensure an attractive aggregate is used in the mix.

Another alternate concrete finish is to colour the concrete with an oxide or pigment that is mixed with the concrete prior to delivery. This can work very well if you only need a single delivery of concrete as the oxide will be thoroughly mixed and the resulting colour will be consistent. Multiple deliveries risk colour variation so special care needs to be taken. If you are mixing your own concrete, the use of oxides is not recommended due to the very high risk of the variability between mixes.

A further alternative is to simply paint your driveway with a concrete paint. These paints are very durable and are usually available in a good range of colours. If you choose this option, ensure that the paint comes with grit premixed, or mix the grit into the paint yourself before application. This will make the surface ‘non-slip’. Sand can be used as a substitute for grit however, the result can be somewhat abrasive on feet.

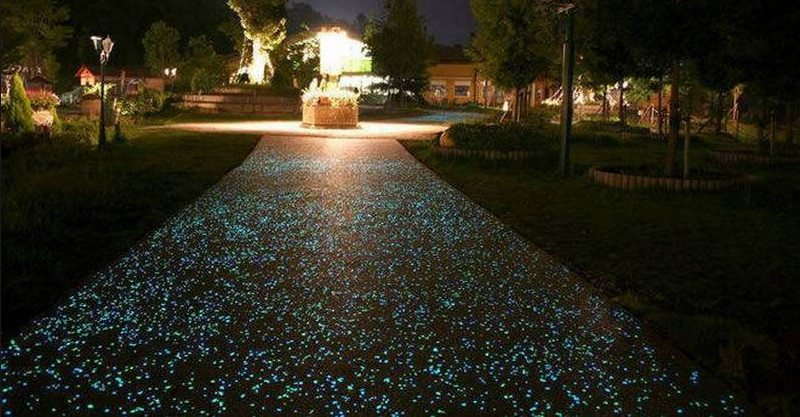

In recent times, ‘glow in the dark’ paints have been developed that put painted concrete in a whole new light. Yes, the pun was intended 🙂 These paints emit a faint light (glow) for three to four hours after sunset.

Stamping and stencilling are also options for new and existing concrete drives respectively. New drives can have the stamping embedded into the surface so that it is absolutely permanent.

Existing drives can be stencilled using an epoxy system that sits on top of the existing surface. While not permanent, epoxy stencilling, when properly applied, will look very good for at least 10 years. The expoxy stenciling is also relatively elastic and can be used to cover up unsightly minor cracks.

If laying a new concrete drive, the minimum thickness needs to be 100 mm (4 inches). If trucks are going to use the driveway, a minimum thickness of 125 mm (5 inches) is needed. All concrete should be reinforced with steel to prevent settling and cracking. You must also ensure adequate expansion joints are installed.

Paving:

Paved driveways are potentially the most expensive solution. In addition to the material cost of the pavers and the laying costs (an easy DIY project), you need to consider the preparation costs.

If you decide to pave your driveway, it is strongly recommended that you lay down a 2 to 3 inch concrete base first. This will ensure that your paved surface never distorts. If you choose to pave without a concrete base, it is critical that you lay down a minimum 3 to 4 inch base of well compacted crusher dust and that you use a paver specifically designed for heavy traffic. Failure to do this will result in damage the first time a truck comes on to your drive.

Grass blocks:

A final alternative you might consider is grass blocks. Known by various commercial names such as turf block, these provide an attractive, and environmentally sound option. In recent years, grass blocks have become a beneficiary of plastic technology, making them cheaper and easier to lay. Traditional concrete grass blocks are still available if you prefer.

The advantage of a grass block driveway is that it is visually far less intrusive than any other form of surfacing.

Comparing costs:

This is always the hardest part. Are you comparing apples with apples? Prices can also vary markedly between areas and countries. The following prices should be taken only as a rough guide and do not include the inevitable preparation costs such as excavation.

Gravel: From $10 per square metre.

Bitumen: from $25 per square metre.

Hot mix: from $50 per square metre.

Concrete: from $60 per square metre

In summary, driveways are as individual as the houses they lead to and the owners who live in those houses. Your choice will depend on your budget and your tastes. A gravel driveway is easy to install, very cost-effective and easily repaired. If you prefer a hard surface, concrete, pavers laid on concrete, and the grass blocks will provide the most economical, long-term solution.

If you are in Australia and would like to get quotes for driveway repairs or installation, go here…

If you are in the USA, you can get no-obligation quotes here…

We hope that helps with your choice. If you have any questions or suggestions please use the comment box below…