Last Updated on March 15, 2024 by teamobn

We all know that pallets are a fantastic material for furniture due to their durability, versatility, and low cost. That’s why pallet furniture is a hit worldwide. Pallets that can be used to create a wide variety of furniture pieces, from coffee tables to sofas to beds. Building furniture with pallets is a great way to upcycle this versatile material, and it can also save you a lot of money.

We’ve seen some great pieces of furniture made from pallets that would be perfect for any home. From dining and coffee tables to beds and bookshelves, there’s something for everyone. We even saw a few beautiful pieces of lounge garden furniture that a skilled DIYer could probably assemble at a weekend!

Pallets are typically very durable, which is great for their intended purpose. However, this can also make them tricky to take apart, especially if you don’t have the right tools. In some cases, Trying to disassemble a pallet without the proper tools or technique can be frustrating and even dangerous.

Do you love pallet projects, but hate the process of taking them apart? You can DIY this tool and you’ll enjoy building with pallets even more! With this handy tool, you can quickly and easily take apart pallets without all the hassle.

It’s the perfect way to enjoy all the benefits of pallet projects without any of the drawbacks. Give it a try and you’ll see just how easy it is to take pallets apart with this DIY tool.

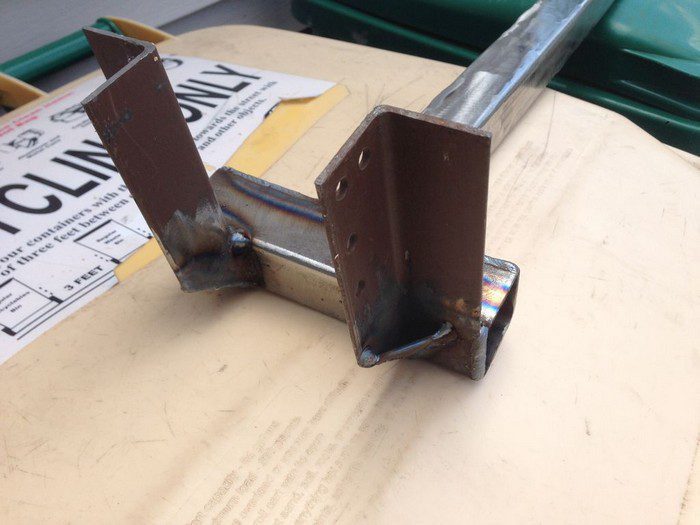

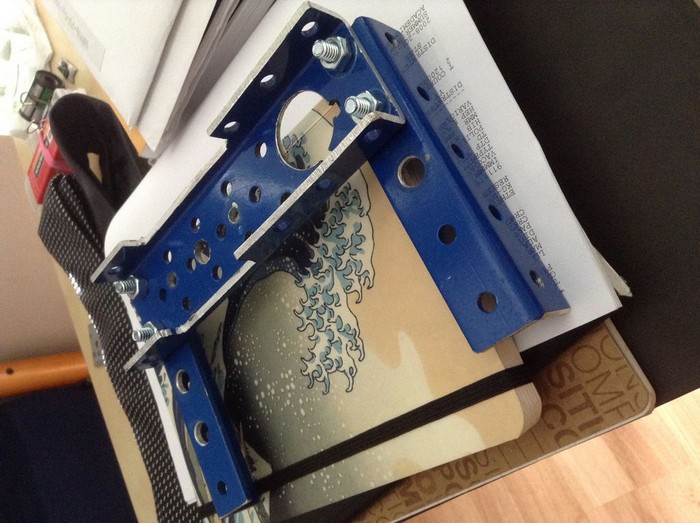

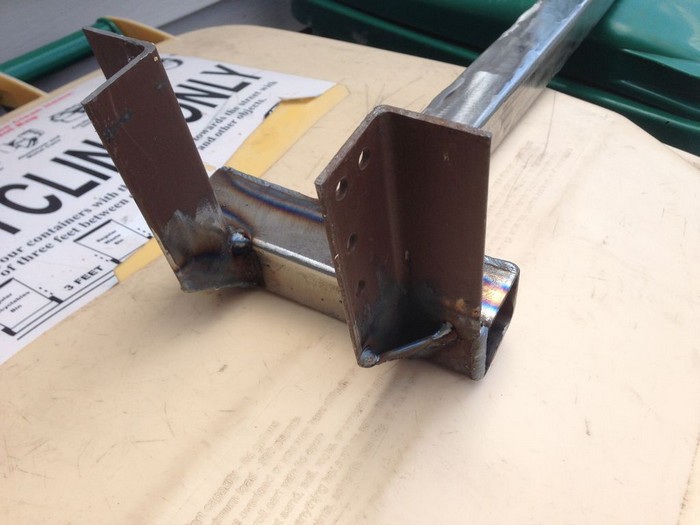

This pallet breaker can be made from different scrap metals and old yard tools. No expensive materials are needed, only some welding skills are required. This project is perfect for those who are looking for a way to recycle old materials and create something useful. With a little bit of time and effort, you can create a pallet breaker that will make your life much easier.

The idea behind a pallet breaker is very simple and straightforward – you can easily figure out how to make your pallet breaker as long as you have access to welding equipment. With just a few basic supplies and a little bit of know-how, you can easily construct a pallet breaker that will make short work of breaking down pallets for recycling or other purposes.

Remember to make the fork of your pallet breaker wide enough to accommodate a 4-inch stringer. If the pallet breaker doesn’t fit the pallet, you can first remove one slat using a hammer. Then, simply align the pallet breaker with the slats on the side of the pallet and drive it through the slats.

If you’re planning on working on a big project that requires dismantling several pallets, this DIY tool will surely help a lot, making the job easier and faster! With its long, sturdy handle and durable blades, this tool will make quick work of any pallets you need to take apart. So save yourself some time and hassle – and pick up a pallet breaker today!

If you want some inspiration on how to create your pallet breaker, you can check out the gallery below showing different versions of this DIY pallet breaker to get some ideas on what metal parts you can use when building your pallet breaker!

Do you know someone who needs this pallet breaker, too?

How to Make a Pallet Breaker

You’ll need these materials:

- Metal Scrap (Bed Frame Angle Iron, Black Pipe, Square Tubing, Shovel Handle)

- Bolts and Nuts

- Wooden Rod

And these tools:

- Angle Grinder

- Welding Machine

Click on any image to start the lightbox display. Use your Esc key to close the lightbox.![]()

Steps:

Step 1: Gather Materials and Safety Gear

Before starting the project, gather all the necessary materials and safety gear. Ensure you have a suitable work area with proper ventilation and wear safety glasses and work gloves to protect yourself from any sharp edges or metal shavings.

Step 2: Prepare the Metal Scrap

Using a saw or angle grinder, cut the metal scrap to the desired lengths. The length of the metal pieces will depend on the size of the pallets you plan to break and the design of your pallet breaker tool. Aim for pieces that are approximately 12-18 inches long for the arms and 24-36 inches long for the handle.

Step 3: Mark and Drill Holes

Using a measuring tape and marker, mark the locations for drilling holes in the metal scrap. You’ll need to drill holes at both ends of each metal piece to attach them with bolts and nuts. Ensure the holes are evenly spaced and aligned to ensure a secure connection.

Step 4: Drill Holes

Secure the metal scrap to a work surface using clamps or a vice to prevent it from moving while drilling. Use a drill with a metal drill bit to drill holes at the marked locations. Start with a smaller drill bit size and gradually increase the size until you reach the desired diameter for the bolts.

Step 5: Attach Metal Pieces

Once all the holes are drilled, assemble the metal pieces to form the arms and handle of the pallet breaker tool. Insert bolts through the holes and secure them in place with nuts using a wrench or socket set. Ensure the bolts are tightened securely to prevent any movement or loosening during use.

Step 6: Attach Wooden Rod

Next, attach the wooden rod to one end of the handle using bolts and nuts. The wooden rod will serve as the handle grip, providing a comfortable and ergonomic grip for operating the pallet breaker tool. Secure the wooden rod in place tightly to ensure it does not come loose during use.

Step 7: Test and Adjust

With the pallet breaker tool assembled, perform a test run to ensure everything is working correctly. Try breaking apart a small pallet or wooden crate to gauge the effectiveness and durability of the tool. If necessary, make any adjustments or modifications to improve performance and functionality.

Step 8: Finishing Touches

Once you’re satisfied with the pallet breaker tool’s performance, you can apply a coat of paint or finish to protect the metal surfaces and enhance its appearance. Additionally, consider adding rubber grips or padding to the handle for added comfort and grip during use.

With just a few simple steps and some basic materials, you can create a functional and durable pallet breaker tool to tackle your DIY projects with ease. By repurposing metal scrap and utilizing basic hardware, you not only save costs but also contribute to reducing waste and promoting sustainability. So, roll up your sleeves, get creative, and enjoy the satisfaction of crafting your pallet breaker tool for all your woodworking adventures.

Thanks to walkthewalk for this great idea!

Wrapping It Up

Crafting your pallet breaker tool is a rewarding DIY project that offers numerous benefits. By repurposing metal scrap and utilizing basic hardware, you can create a functional and durable tool to tackle your woodworking projects with ease. Throughout the process, you’ll develop valuable skills in metalworking, drilling, and assembly, enhancing your DIY capabilities.

Creating a pallet breaker tool allows you to customize the design to suit your specific needs and preferences. Whether you’re breaking down pallets for woodworking projects, home renovations, or upcycling furniture, having a reliable pallet breaker tool at your disposal can save time and effort.

Building your pallet breaker tool promotes sustainability by repurposing materials that would otherwise end up in the landfill. By giving new life to metal scrap and wooden rods, you’re reducing waste and minimizing your environmental footprint.

Additionally, DIY projects like this foster a sense of accomplishment and pride as you witness your creation come to life. From cutting and drilling to assembly and testing, each step of the process provides a tangible sense of progress and achievement.

By taking on DIY projects, you’re empowering yourself to solve problems and overcome challenges independently. Instead of relying on store-bought solutions, you’re embracing your creativity and resourcefulness to meet your needs.

So, are you ready to embark on the journey of crafting your pallet breaker tool today?

Frequently Asked Questions

1. How difficult is it to make a pallet breaker tool?

The difficulty level can vary depending on your familiarity with metalworking and DIY projects. However, the steps outlined in the guide are relatively straightforward, making it accessible for beginners with some basic skills and tools.

2. Can you customize the design of the pallet breaker tool?

Yes, one of the advantages of making your pallet breaker tool is the ability to customize the design to fit your specific needs and preferences. You can adjust the size, shape, and features of the tool to suit your woodworking projects.

3. How long does it take to make a pallet breaker tool?

The time required to complete the project will depend on your skill level, the complexity of the design, and the availability of materials and tools. On average, you can expect to spend a few hours from start to finish.

4. Is it cost-effective to make a pallet breaker tool compared to buying one?

Making your own pallet breaker tool can be cost-effective, especially if you already have some of the materials and tools on hand. Additionally, repurposing metal scrap reduces the need to purchase new materials, making it a budget-friendly option.

5. What safety precautions should you take when making a pallet breaker tool?

It’s essential to wear safety glasses and work gloves to protect yourself from sharp edges and metal shavings. Additionally, work in a well-ventilated area and follow proper safety protocols when using power tools such as saws and drills.